Good health is not a short-term goal, it is important to put in effort everyday. To support your efforts towards achieving good health, we take it upon ourselves to deliver reliable products that are safe for your consumption.

In order to deliver safe products for your consumption at any time, we have set strict standards so as to maintain the safety and steady supply of the product. Regardless how far we have come since the start of this health supplement business, we will strive to keep our eyes fixed on the starting point as well as our primary purpose of starting this business, and fulfil our promise to produce quality products.

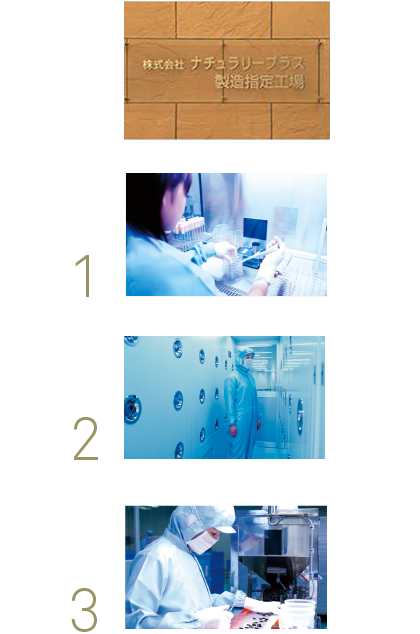

The manufacturing process takes place in our selected factory that is situated at the foot of Mount Fuji, surrounded by lush greenery and clear water. It is also certified to be in compliance with Good Manufacturing Practice※1 (GMP) for dietary supplements and ISO 22000 standards※2, ensuring that only safe and high-quality products are produced.

Upon receiving the raw ingredients, they are subject to strict microbial, chemical and other tests.

Factory workers are required to comply strictly with cleanroom regulations such as wearing designated clothing for the cleanroom, and removing of dust in the air shower room before entering the production room.

Visual inspection of individual capsules is conducted to ensure that even the hard-to-detect irregular capsules will be filtered from the production line.

※1 Standards set to control manufacturing process and ensure product quality for dietary supplements. By manufacturing and performing appropriate quality checks according to these strict standards, we produce high quality products.

※2 An international standard of the food safety management system. A standard that comprises a mix of technological standards and HACCP (Hazard Analysis and Critical Control Point: a system used in the identification, assessment and management of important risk factors related to food safety) to ensure food safety in the manufacture, distribution and sale of food.